Environmental impact of semiconductor manufacturing for solar applications

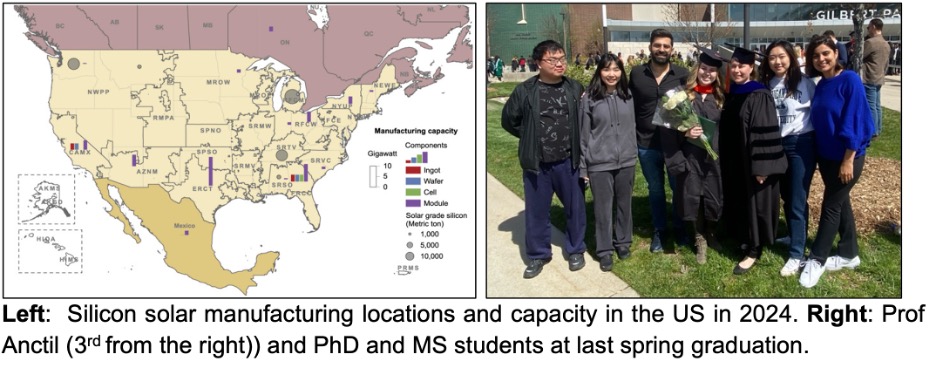

The annual solar installation in the US needs to increase from 22 GW in 2022 to 140 GW per year to meet the climate goals. As a result, large amount of semiconductor material will be needed to produce solar modules. The student will identify the type and amount of semiconductor material needed to manufacture solar modules globally and specifically for the United States. The location of current mines, methods for transformation, and distance to existing semiconductor manufacturing facilities will be considered. In addition to primary production (from mines), we will consider the potential for recycled semiconductors from solar and other applications. Students will learn to use the life cycle assessment software SimaPro to evaluate the impact of producing semiconductor materials for solar photovoltaics from primary and recycled materials. During the 10-week program, the student, with the help of a graduate student mentor, will identify semiconductors of interest, develop manufacturing scenarios considering various locations for mining and recycling, and calculate the environmental footprint (carbon and water footprint, for example) of semiconductor manufacturing in the US. The results will be presented to our group and at the MSU-wide undergraduate research conference.

Scientific goals:

- Identify material availability from primary and recycled sources for solar manufacturing.

- Our ultimate goal is to understand the environmental impact of solar semiconductor manufacturing in the US and the impact of primary and recycled semiconductor production.

Student learning goals:

- Learn and use a life cycle assessment software (SimaPro) to calculate the environmental footprint of a product

- Calculate the amount of material needed based on current and future solar technologies